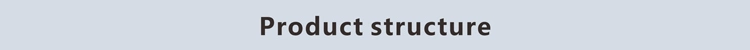

3A Sanitary Single-Stage Emulsified Homogeneous Mixing Pump for Dairy Processing

Basic Info

| Max. Power | 90kw |

| Temperature | -20~140degree |

| End Connection | Threaded, Clamped, Flanged |

| Transport Package | Wooden Case |

| Specification | DJ-JZ3 |

| Trademark | DONJOY |

| Origin | China |

| HS Code | 8413602190 |

| Production Capacity | 30000sets/Year |

Product Description

| Item Name: | 3A Sanitary Multi-Stage Emulsifying homogenizer pump for Dairy Processing Daily Chemicals Cheese Sauce |

| Material: | SS304 or 316L/1.4404,ASME BPE 316L |

| Seal Material: | EPDM (Standard, FDA approval), or FPM (Viton) |

| Max. Flow: | 50 m3/h |

| Max. Power: | 90KW |

| Media refinement: | ≤ 100 GRIT (≈200 μm) |

| Temperature: | -20~140 degree centigrade |

| Surface treatment: | ≤RA 0.8μm, ≤RA 0.6μm, ≤RA 0.4μm |

| Mechanical seal: | Single mechanical seal & double mechanical seal |

| Motor: | ABB/or others |

| Motor Frequency: | 50HZ, 60HZ |

| Available connection: | Clamped, Threaded, Flanged, Aseptic flanged |

| Available standard: | DIN, SMS, 3A, RJT, ISO, IDF |

| Operated: | By electic motor |

| Low discharge : | Diaphragm valve/ball valve/butterfly valve |

| Certification: | 3-A-02-11(N.O.1579); MD/06/42-EC(N.O.70521616101-00); FDA 177.2600;USP CLASS-II; EG/VO1935/2004; |

| Application range: | Food, beverage, pharmacy, health protection, fine chemistry, coating, pesticide,daily chemical and papermaking etc. |

| Packaging Details: | By plywood case |

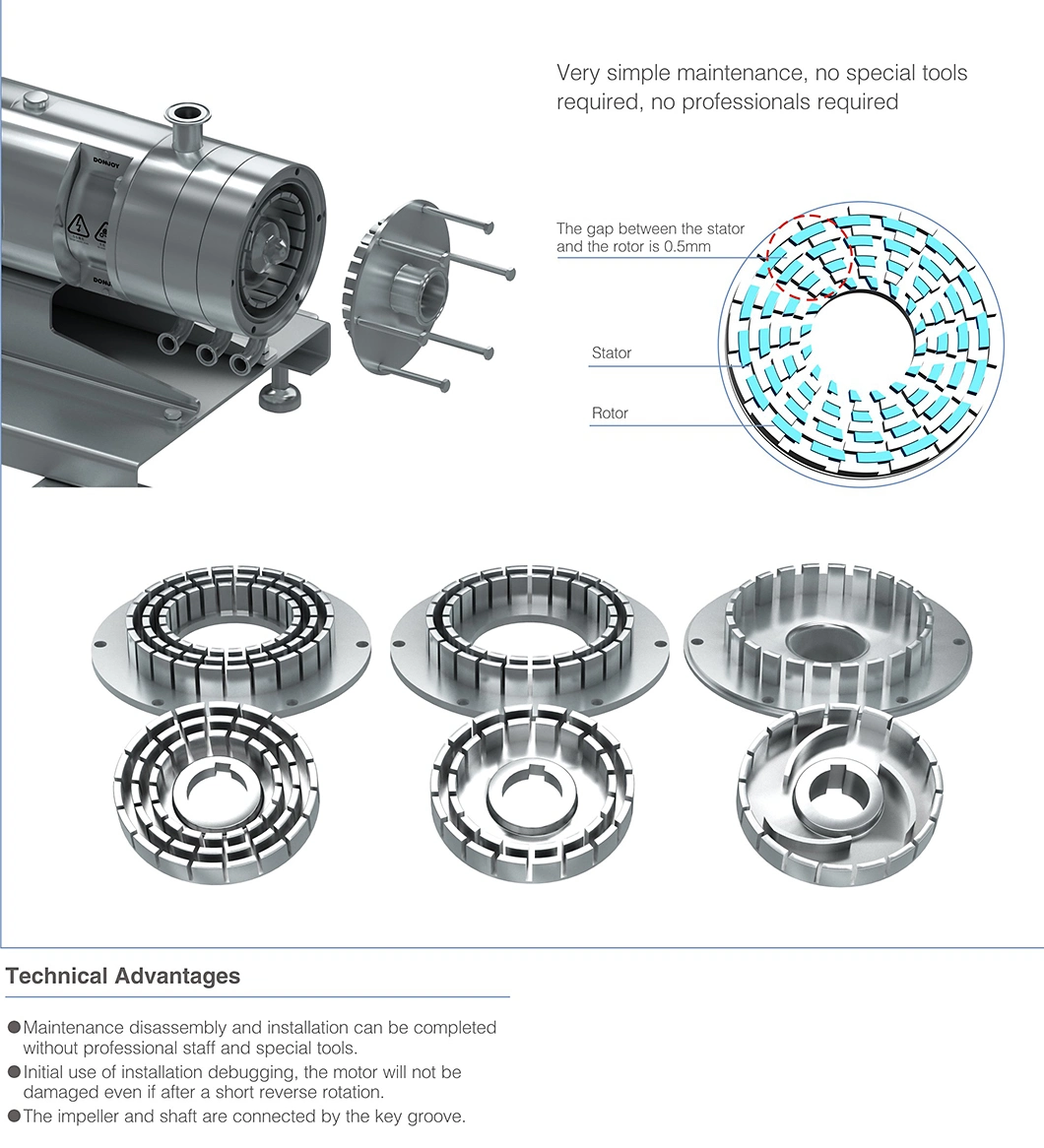

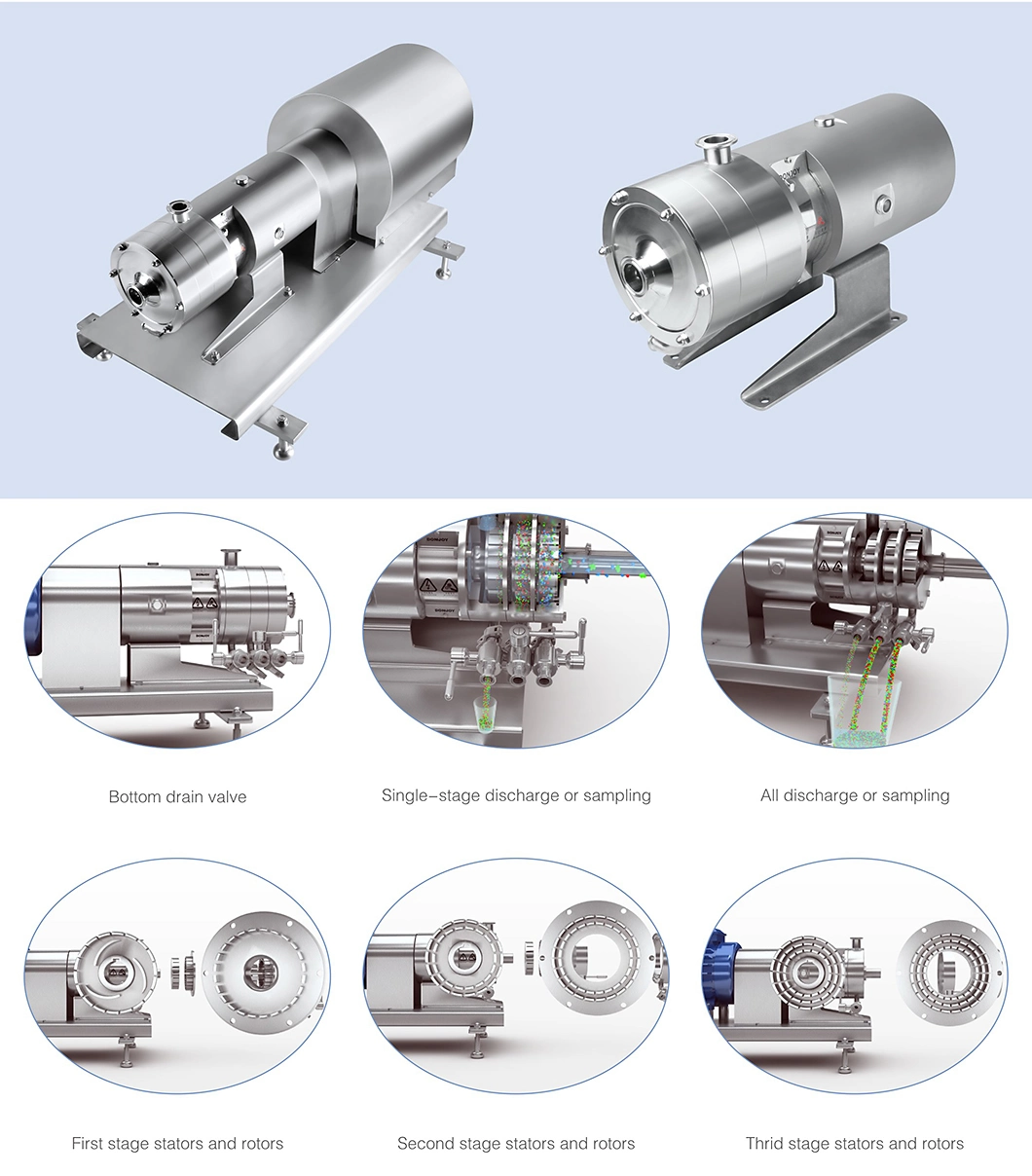

3A Sanitary Multi-Stage Emulsifying homogenizer pump for Dairy Processing Daily Chemicals Cheese SauceSolutions for high-efficiency,dispersion,cut refinement,smash,emulsification,mixing,homogenization,high purity

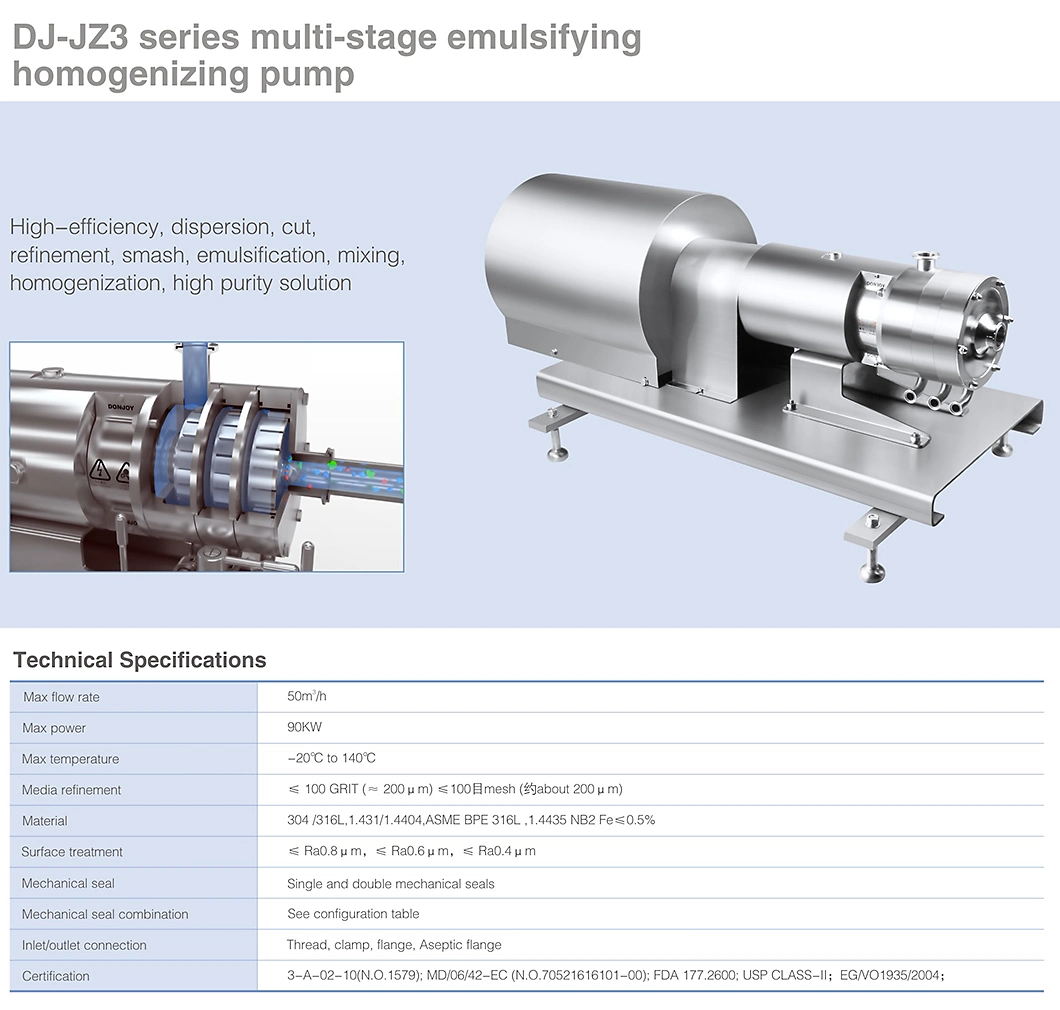

Features:

1, Large capacity, suitable for industrial on-line continuous production;

2, Particle size distribution range narrow, high uniformity;

3, Saving energy, time and efficiency;

4, Low noise, smooth operation;

5, Eliminate the production quality discrepancy between batches;

6, No dead ends, material 100% through the dispersing and shearing;

7, With short distance, low head delivery function;

8, Easy to use, easy maintenance;

9, Can achieve automation control;

10, Significantly shorten the process time, to achieve the complete dispersed effect;

11, Complete elimination of fish-eye, clot;

12, Easy to clean online - CIP.

If you have any inquiry, please leave message below and "Click Send "