High Shear Emulsifying Inline Homogenizing Pump for Cosmetics Creams

Basic Info

| Model NO. | HD |

| Layout Type | Horizontal |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Milling, Emulsifying, Mixing |

| Operating type | Continuous Operating |

| Condition | New |

| Power | 1.5kw to Customized |

| Voltage | 220V-480V, 50/60Hz, 3phase |

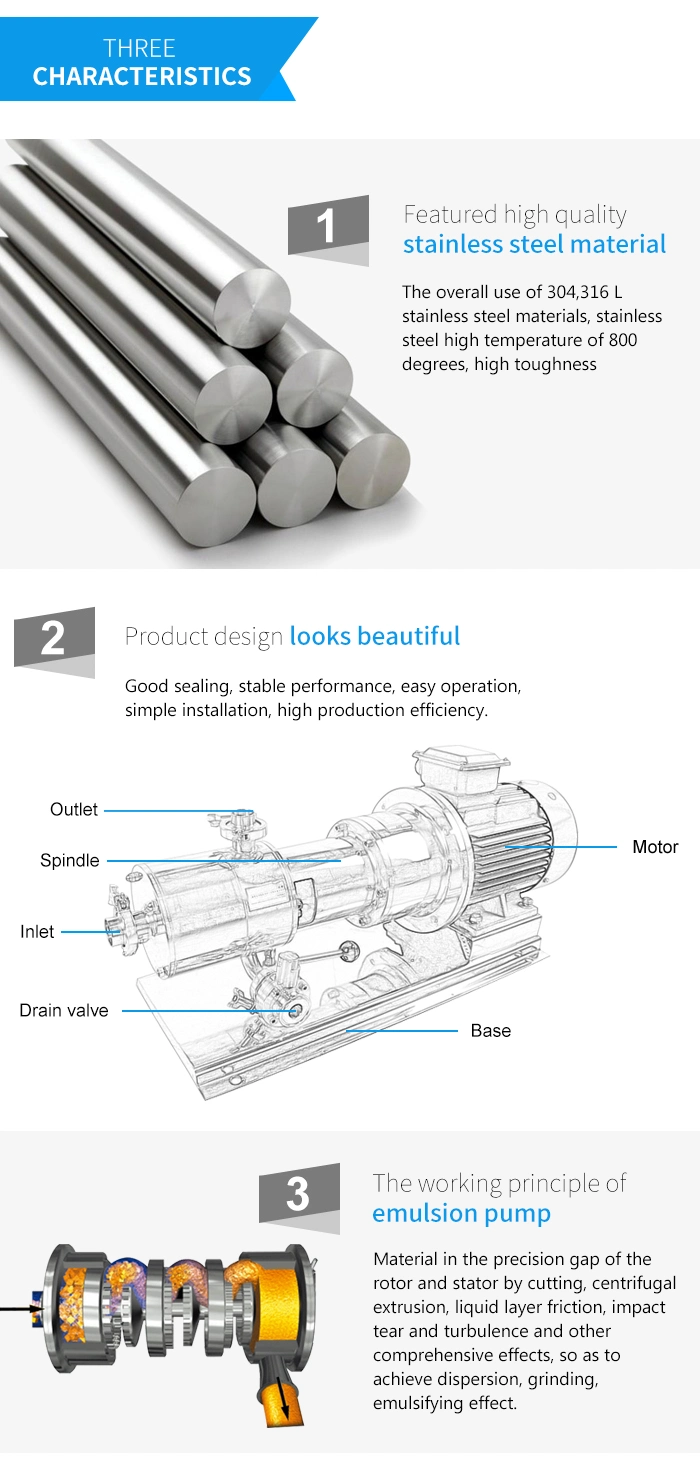

| Material | SS304/SS316(L) |

| Flow | 0-140m3h |

| Speed | 2800r/Min |

| Teeth Type | Thick Teeth, Middle Teeth, Thin Teeth |

| Rotor | 3 |

| Usage | Food, Chemical, Pharmacy, Cosmetic, Ects |

| Stator | 3 |

| Motor | Domestic, ABB, Siemens |

| Transport Package | Plywood Case |

| Specification | Customized |

| Trademark | HUNDOM |

| Origin | Guangzhou |

| HS Code | 8413709990 |

| Production Capacity | 100 Set/Sets Per Month |

Product Description

Tag:Stainless Steel Latex Pump/Emulsion Pump/Paint Pump/Grease Homogenizer

Structure

High Shear Pump is a high shear mixer for inline or continuous operation. In the Inline process, the mixer is installed outside the tank. This makes it easy to be built into an existing production line with normal inlet/outlet connections. In the case to deal with liquid with a low viscosity, the BRL-3 series High Shear Pump can pump the liquid without an additional pump. That is why it is also called High Shear Pump. The BRL-3 series High Shear Pump can be used to deal with the product in a single pass or with several circulations to make the product better. The multi-stage (usually three-stage) High Shear Pump has three sets of stator/rotor systems to enhance its shearing performance. This design dramatically reduces processing time, and in some cases only one pass through the mixer can lead to satisfied products.

Technical Parameters

| Model | Power(kw) | Speed(rpm) | Flow(m³/h) |

| HD-60 | 4 | 2800 | 0-4 |

| HD-100 | 7.5 | 0-8 | |

| HD-120 | 11 | 0-12 | |

| HD-140 | 15 | 0-18 | |

| HD-165 | 22 | 0-22 | |

| HD-200 | 37 | 0-30 | |

| HD-220 | 55 | 0-40 | |

| HD-240 | 75 | 1480 | 0-55 |

| HD-260 | 90 | 0-65 | |

| HD-300 | 110 | 0-80 | |

| HD-360 | 132 | 0-100 | |

| HD-380 | 160 | 0-120 | |

| HD-400 | 185 | 0-140 |

Advantages

<<Save your processing time by up to 90%<<Increase the end product uniformity<<Save your cost of lots of agitators & pipelines<<Easily adapted into an existing production line without change of the layout<<Compact size requiring small space<<Hygienic design for food & pharmaceuticals<<Various interchangeable stator/rotor for different materials to be handled<<Complete stainless steel construction to meet the strict hygienic requirement<<Multiple stage stator/rotor for single pass processing to save more time but a better uniformity<<Double mechanical seals with thermosyphon tank to cool the seals<<Contact parts to be built in SS304, SS316L.<<Dull polishing or mirror-like polishing

Product Show

About HUNDOM

Guangzhou Hundom Machinery Equipmenthas been manufacturing colloid mill, jacketed kettle, rotor pump, mixing tank and other machinery equipment for 15 years , putting quality as our first consideration. We own a team with rich experience in the field, if you have any question, contact us for the professional answer.

Guangzhou Hundom Machinery Technology.Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, ChinaSales:Shum Welcome to visit our factory !