Ice Cream Emulsifying and Homogenizing Mixer Pump

Basic Info

| Layout Type | Horizontal |

| Additional Capabilities | Pumping |

| Operating type | Continuous Operating |

| Condition | New |

| Series | Fhm1, Fhm2, Fhm3 |

| No.S of Rotor and Stator | Single, Two Stage, Three Stage |

| Connection Type | Clamp, Thread, Flange |

| Function | Mixing, Dispersion, Breaking, Dissolution, Refiner |

| Seal Type | Double Flushed Mechanical Seal |

| Contact Material | SS304, 316, 316L or Others |

| Transport Package | Plywood Case |

| Trademark | Bonve |

| HS Code | 847982 |

| Production Capacity | 5000sets/Year |

Product Description

Ice Cream emulsifying and homogenizing mixer pump There are many stabilizers and emulsifiers in ice cream. Bonve ice cream homogenizer mixing pump can successfullydisperse and hydrate stabilizers and emulsifiers because it meets the following process requirements:1. The powder and liquid mixing system is fast enough to incorporate the powder and disperse it into the mixture.2. Stabilizers/emulsifiers tend to cling when added to the base fluid, so the mixer must be able to break these down.3. The stabilizer/emulsifier must also be reduced to the smallest particle size possible to maximize yield. Some products will not" activate" unless the granularity is sufficiently reduced.Product Description

Bonve high shear emulsifying and homogenizing mixer is a high-efficiency product integrating mixing, dispersing, crushing, dissolving, refining, depolymerizing, homogenizing and emulsification. After using this series of products, the original traditional production process is further simplified, the production efficiency is greatly improved, and the product quality is significantly improved. Homogenization is an important step in creating the high-quality products that consumers expect. The benefits include improved product taste, texture and consistency, which then translate into increased sales and customer satisfaction. Bonve homogenizer mixer are widely used in petrochemical, refinery chemistry, consumer chemicals, biology pharmaceutics, foods processing, paper-making, environmental protection, pain and so on.

Features:

100% dispersive shear;Quickly dissolves solids without agglomeration; No dead ends, high evenness;Time-saving, high-efficiency, low-consumption; Simple operation, convenient maintenance, and can realize automatic control.

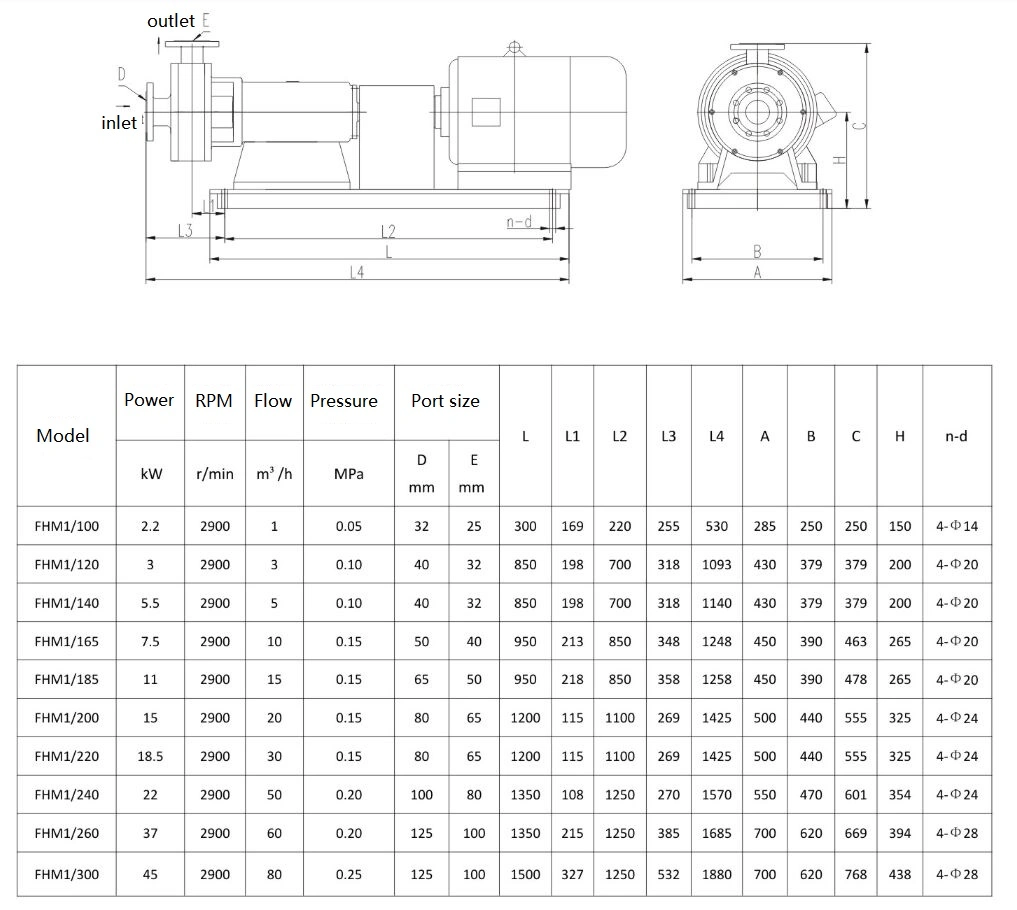

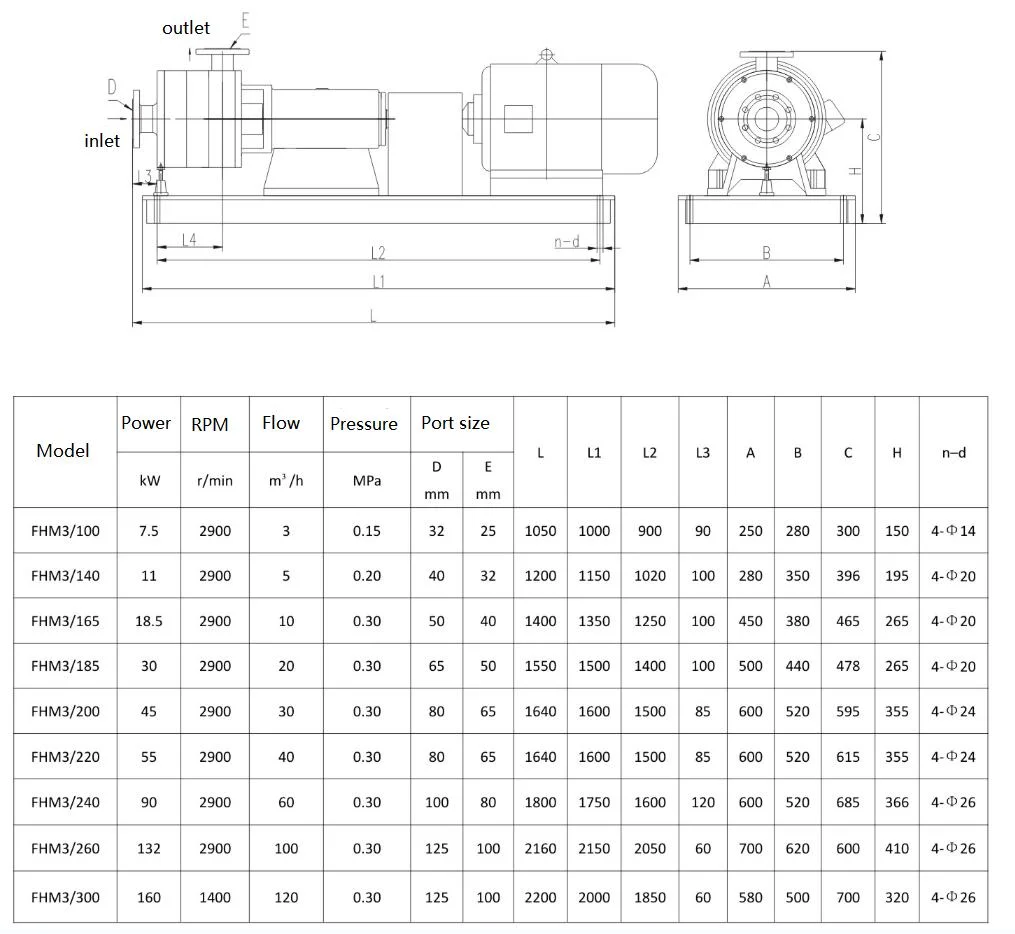

Bonve emulsifying and homogenizing shear pumps are mainly devided into 2 series based on different numbers of rotor and stator, working types. (The pump with 2-stage rotor and stage can be made as per request)FHM1 series with single stage rotor and statorFHM1 series is equipped with one set multi-layer stator and rotor. Required to be used in the cyclic processing of medium and small batch production. For short distance transmission, homogeneous and emulsion.FHM3 series with three stage rotors and statorsFHM3 series is an extension of the FHM1 series. The working chamber is composed of three-stage rotor and stator. For applications that require greater and quicker homogenizing and emulsifying, FHM3 is used. It can be used in the cyclic processing of medium and large-scale production.

Product ParametersFHM1 series

| Model | Electrical Power(Kw) | Rotation Speed(r/min) | Capacity(m3/h) | Pressure(Mpa) | Diameter of inlet/outlet |

| FHM1/100 | 2.2 | 2900 | 0-3 | 0-0.05 | DN40/40 |

| FHM1/120 | 4 | 2900 | 0-4 | 0-0.1 | DN40/40 |

| FHM1/140 | 5.5 | 2900 | 0-5 | 0-0.1 | DN50/40 |

| FHM1/165 | 7.5 | 2900 | 0-8 | 0-0.15 | DN50/40 |

| FHM1/185 | 15 | 2900 | 0-15 | 0-0.15 | DN65/50 |

| FHM1/200 | 22 | 2900 | 0-20 | 0-0.15 | DN80/65 |

| FHM1/220 | 30 | 2900 | 0-30 | 0-0.15 | DN80/65 |

| FHM1/240 | 37 | 2900 | 0-50 | 0-0.2 | DN100/80 |

FHM3 series

| Model | Electrical Power(Kw) | Rotation Speed(r/min) | Flow rate(m3/h) | Discharge pressure(Mpa) | Diameter of inlet/outlet |

| FHM3/100 | 5.5 | 2900 | 0-3 | 0.1 | DN40/40 |

| FHM3/120 | 7.5 | 2900 | 0-4 | 0.15 | DN40/40 |

| FHM3/140 | 11 | 2900 | 0-5 | 0.2 | DN50/40 |

| FHM3/165 | 18.5 | 2900 | 0-10 | 0.3 | DN50/40 |

| FHM3/185 | 30 | 2900 | 0-20 | 0.4 | DN65/50 |

| FHM3/200 | 45 | 2900 | 0-30 | 0.5 | DN80/65 |

| FHM3/220 | 55 | 2900 | 0-40 | 0.5 | DN80/65 |

| FHM3/240 | 90 | 2900 | 0-60 | 0.6 | DN100/80 |

Remarks:

1. Above dates are tested by water. For product with poor liquidity or require a higher discharge pressure, Bonve lobe pump is advised to be installed before the homogenizer for transferring.

2. Port size can be changed as needed. Flange connection as starndard, clamp and thread as optional.

3. Motor matched is Siemens, Siemens or equivalent brand. Normal type with 3ph/380V/50Hz as standard.

4. MOC: SS304 as standard, SS316, 316L and others as optional. 150°C (302°F) anti-heat seal.

5. Bonve reserves the right to change specifications without prior notification.

To selec a right model for your application, pls fill in the below table and send to us

Your industry/application |

|

Processed medium's name |

|

Medium's feature | Sanitary ( ) Corrosive ( ) Poisonous ( ) |

Medium's proportion | Liquid % ____ Density____ Viscosity____ PH value____ Solid % ____ Solid size ___ |

Processing requirement | Mixing dissolving ( ) Dispersed suspension ( ) Emulsification ( ) Homogeneity ( ) Reaction ( ) Powder liquid mixing ( ) |

Working type | Continuous circulation work ( ) Continuous non-circulation work ( ) Batch type ( ) |

Working temperature | |

Particle size | Before processing _______ After processing ________ |

Handling capacity required | |

Delivery head/pressure required | |

Vessel's dimension | |

Existing pipe size and connection type | |

The existing process equipment and the existing problems |

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS, ISO9001:2015 approved company. Providing its customers with customized pumping and mixing solutions and solving their problems during the production. Bonve has more than 20 years of expertise and technical know how. We design, R&D and produce. When you choose a Bonve pump, you not only get the high quality pumps, but you also get the advantage of Bonve's engineering expertise and years of application knowledge in the food, chemical, pharmaceutical, cosmetics industries etc.By 2021, we have obtained more than 30 patents, such as invention patents, utility model patents. Owns one set of full automatically pump testing system, 98 sets of advanced CNC machines, including mills, borers, lathes, drillers, grinders, machining centers etc. and a variety of precise inspection equipment.Bonve pumps are acknowledged and used over 40 countries around the world. By 2021, more than 5000 companies used Bonve pumps and over 60000 units pumps are running in the world. Time and again companies specify Bonve Pumps as the "standard" equipment for their manufacturing processes. We are looking forward to be partner with you.

How guarantee the supplied pump is the best choice?

--To ensure satisfactory performance of pump, it is important that the pump must be properly selected firstly. We select the pump according to your characteristics of medium and condition of the technological requirements, bring you the right pump for your critical process.--With more than 20 years (2001-2021) industry experience, offering rich and actual solution. Pumps we sold out has been over 600,000units running in the world.--Customers we served from various industries more than 5,000 including food, beverages, daily chemicals, pharmacy, pulp and paper, coating and painting, oil and gas, biotechnology etc.

How you control quality?

--Organized control to select and evaluate of our vendors.--Incoming inspection for all the raw meterails.--Quality process controla. Raw material inspectionb. Process spare parts according to approved drawingsc. Assemble the pump based on customs using conditiond. Test pump's performance (record flow rate, discharge pressure,current and temperature)e. Inspecting conformity--All the pump main parts are processed by CNC maching, high-precision fabrication

What is your Warranty?

We guarantees that the pumps supplied are of high quality and reliability. Warranty is 18 months from the date of manufacturing. If any quality problem, we will send you the parts without cost in 3 working days.

How to operate your pump properly?

We have the complete English manual, training file and vedios to guide how to install the pump, how to maintain pump.