Stainless Steel Sanitary Food Chemical Grade Positive Displacement Rotary Lobe Pumps

Basic Info

| Model NO. | BV |

| Rotor Material | SS304, SS316, SS316L |

| Pump Installation | Fixed, Movable with Trolley |

| Motor Installation | Horizontal, Vertical |

| Seal Type | Single Face, Double Face Mechanical Seal |

| Transport Package | Plywood Case |

| Specification | Less 1 CBM |

| Trademark | Defu |

| Origin | China |

| HS Code | 8413603190 |

| Production Capacity | 2000units Per Year |

Product Description

Brief introduction

YL rotary lobe pump is self-priming, valveless, positive displacement pumps. With the characteristics of low rotation speed and high output torque, pump shows its talents to transfer high viscosity liquid products. Its unique working principle works with a strong drive system, ensure that the pump can output a strong driving torque at low speed, can guarantee continuous, non-stagnant transferring, and ensure that the transferred material not damage, viscosity can be as high as 1500000CP.Pump Applications

Pump Working principle

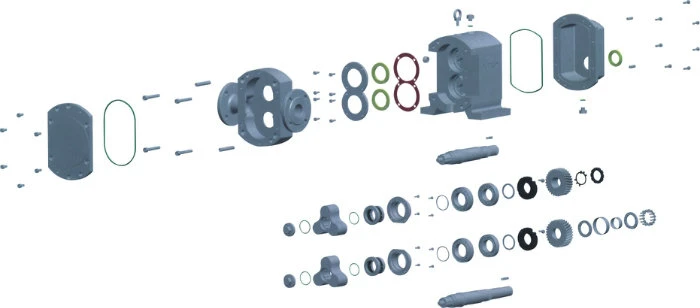

Pump Structure

Complete pump consists of bare shaft pump, coupling& shield, gear reduer with motor and baseplate. You can only have our bare shaft pump.

Pump Specifications

Model | Displace-ment (L/r) | Speed range (r/min) | Capacityrange(M³/h) | Max.Pressure (Mpa) | Power (Kw) | Suction pressure (Mpa) | Inlet &outlet (mm) | Max.Viscosity (cp) |

25BV12-2 | 0.15 | 20-600 | 0.09-4.32 | 1.2 | 2.2 | -0.02~-0.08 | 25 | 1000000 |

40BV12-5 | 0.32 | 20-550 | 0.18-7.92 | 1.2 | 4 | -0.02~-0.08 | 40 | 1000000 |

50BV12-8 | 0.47 | 20-550 | 0.28-12.4 | 1.2 | 5.5 | -0.02~-0.08 | 50 | 1000000 |

50BV12-10 | 0.65 | 20-550 | 0.39-17.16 | 1.2 | 7.5 | -0.02~-0.08 | 50 | 1000000 |

65BV12-20 | 1.74 | 20-550 | 1.04-45.94 | 1.2 | 15 | -0.02~-0.08 | 65 | 1000000 |

80BV12-30 | 2.5 | 20-550 | 1.5-66.00 | 1.2 | 22 | -0.02~-0.08 | 80 | 1000000 |

80BV12-40 | 3.65 | 20-550 | 2.19-96.00 | 1.2 | 30 | -0.02~-0.08 | 80 | 1000000 |

125BV12-50 | 4.6 | 20-420 | 2.76-92.74 | 1.2 | 37 | -0.02~-0.08 | 125 | 1000000 |

125BV12-70 | 6.1 | 20-420 | 3.66-122.98 | 1.2 | 45 | -0.02~-0.08 | 125 | 1000000 |

125BV12-80 | 7.0 | 20-420 | 4.20-141.12 | 1.2 | 55 | -0.02~-0.08 | 125 | 1000000 |

150BV12-100 | 11.4 | 20-420 | 6.84-229.82 | 1.2 | 75 | -0.02~-0.08 | 150 | 1000000 |

150BV12-150 | 12.5 | 20-420 | 7.50-252.00 | 1.2 | 90 | -0.02~-0.08 | 150 | 1000000 |

175BV12-200 | 16.7 | 20-420 | 10.02-336.67 | 1.2 | 110 | -0.02~-0.08 | 175 | 1000000 |

Note* 1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.3. Port size can be changed as needed.4. YL reserves the right to change specifications without prior notification. |

How to choose our pump

Dear Customer,To ensure satisfactory performance of required pumps, it is important that the pump must be properly selected. Below table is for your selection guideline, which is nessary to supply us for a targeted solution and offer.| Selection Guideline | |||

| Buyer information | |||

| Company name | Contact person | ||

| Website | |||

| Address | Mobile No. | ||

| Tel/Fax No. | Online chat ID. | ||

| Liquid information | |||

| Your industry: __________ Liquid name:___________ | |||

| Features: Sanitary[ ] Corrosive[ ] Poisonous[ ] | |||

| Viscosity:_______cp Density:_______ Temperature:_____ºC PH value:________ | |||

| Solid content:_______ Max. size of particle:_______ | |||

| Using condition | |||

| Capacity: Max. required:__________ L/H Working required:__________ L/H | |||

| Discharge pressure: Max. required:__________Mpa Working required:__________ Mpa | |||

| Suction pressure: Max. required:__________Mpa Working required:____________ Mpa | |||

| Delivery head required:____________ Vacuum:________ Mpa | |||

| Heating jacket required: Yes[ ] No.[ ] Heating temp.:_____ºC | |||

| Liquid inlet/outlet direction: Horizontal[ ] vertical[ ] | |||

| Pipe size: Inlet___________ Outlet____________ | |||

| Connection type required: Flange[ ] Thread[ ] Clamp[ ] | |||

| Installation type: Fixed [ ] Movable[ ] | |||

| Operating status: Continuous[ ] Interruption[ ] | |||

| Liquid contact material: SS304[ ] 316[ ] 316L[ ] Others________ | |||

| Special request_____________________________________ | |||

Factory workshop showingPump working at siteWhy us

--More than 18 years of expertise and technical know how.--We design, R&D and produce.--We have obtained 30 patents, such as invertion patents, utility model patents. ISO9001:2015 approved company, CE certified pumps.--Own one set of full automatically pump testing system, over 65 sets of advanced CNC machines, including mills, borers, lathes, drillers, grinders, machining centers etc. and a variety of precise inspection equipment.--A team of senior sales engineers who help end-users solve their problems happened during the design stage to the finish products.--Customers we served from various industries more than 4,000 including food, beverages, daily chemicals, pharmacy, pulp and paper, coating and painting, oil and gas, biotechnology etc. We are not satisfied until our pumps have been successfully integrated into your processes and solve your pumping problem. This is our passion!